The Role of Reverse Logistics in Circular Fashion

Fashion manufacturing requires significant natural resources, and increasing pressure to reduce ‘fast fashion’ models of production are pushing retailers to seek more sustainable processes. One major criticism levied against fashion companies is that returned items are simply dumped, despite being in good condition, contributing to landfill waste and pollution in the Global South. New EU measurements will provide a framework for companies to assess and improve sustainability, keep textiles in use for longer and reduce the lifetime environmental impact of the materials.

Supply chain operations play a significant role in extending the life of textiles, from recycling unusable garments into new fabrics to simply preparing returned clothes for resale. In this article, we will discuss circular fashion, returns processes and how partnerships can streamline both.

Understanding Circular Fashion Models

Circular fashion has a few different models. Some focus on using recycled materials from other industries, as part of a larger circular economy. Others encourage customers to recycle old or damaged clothing through their channels, with the intention of reusing materials within a single business. Still more look to other companies to repurpose their waste materials, such as off-cuts, into new products such as housing insulation.

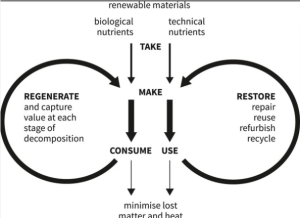

What these various models have in common is a focus on reducing waste to landfill, relying less on making new materials, and extending the life of products.

Linear vs. Circular:

The best way to understand circular business models is in contrast to traditional, linear models. Manufacturing in all sectors traditionally carries materials in a straight line, referred to by Kate Raworth in Doughnut Economics as the ‘Take – Make – Dispose’ pipeline.

- Raw materials are extracted from natural sources, whether cotton, flax, silk or oil for making synthetic fabrics. This extraction has consequences for the environment, whether habitat destruction or pollution.

- They are manufactured into the product through several steps, each with an environmental impact. The product is bought and used for as long as it lasts or is wanted.

- When the product is no longer useful, it is disposed of in landfill waste, or worse, ocean dumping, leading to pollution and danger to wildlife

In a circular business model, the extraction of materials and the disposal of used products are closely linked, with older products being recycled into materials for new ones.

Circular economics also promotes keeping items in use for longer, using more durable materials and stitching and offering multiple styling methods.

Reprocessing & Logistics are Vital for Circular Fashion

To avoid discarding garments unless absolutely necessary, robust reverse logistics for clothing are vital.

For example, when shopping online, many consumers purchase multiple sizes to try on at home. The unwanted items are returned, and typically in near-new condition. Efficient returns management makes these garments ready to be sold again.

When companies do not prioritise reprocessing returns, a high volume of saleable items is disposed of in landfill, often abroad.

A strong reprocessing service helps both high-street and online fashion retailers retain materials, improve wastage numbers and lower their environmental impact, as returned items can simply be resold rather than wasted.

Reverse logistics providers offer advanced solutions, from tailored shipping to streamlined processing centres. Services like these are vital for creating sustainable fashion business models and changing the reputation of fast fashion from polluters to innovators.

Key Components of Reverse Logistics Systems

Technology & Collaboration in Reverse Flows

Smart labelling, mounted scanners and integrated online systems all help us process returns at scale. These technologies allow us to track individual items as they move through our systems, providing reliable data for our clients to manage inventory and distribution.

Industrial ozone cleaning for garments allows us to decontaminate high volumes of clothes at once. Cleaning, repairs and storage processes are all tracked and documented using advanced technology to optimise workflows and provide lower costs for partners.

These efficiencies play a key role in allowing more sustainable product flows, reducing wastage and enabling textile recycling.

Implementing Circularity in Fashion Supply Chains

Creating a sustainable and circular fashion model starts with take-back programs. These are initiatives retailers can organise to collect used products or materials and reintroduce them to the original manufacturing cycle, through recycling and reuse. Take-back programs can also include incentives for participating customers, such as gift-cards or discounts.

Retailers might provide:

- Shipping labels for customers to use for returns

- Mailers for customers to fill with used goods

- Educational and Marketing materials to promote the scheme

In order to make take-back and recycling schemes viable, it is vital to build scalable infrastructure. This includes transport and storage for returned items, and skilled labour to reprocess or recycle the items.

Working with a trusted reverse logistics partner can support your circular fashion take-back program to succeed, particularly one that provides cleaning, repairs, relabelling and more.

Overcoming Challenges & Scaling Circular Programs

Sustainable practices in fashion manufacturing are long overdue, because taking responsibility for recycling and reducing waste is complicated. Many businesses do not have the resources or knowledge to implement these systems, and the cost can create resistance to change among stakeholders.

Address these concerns by working with experienced partners to create realistic returns processes. Start on a small scale and leverage the data gained to design a scaleable, sustainable system that requires no additional labour or space in-house.

ExcelPress provide returns management to manage, rework and refurbish customer returns on any scale, processing 100,000 units per week and with room for growth.

For a free quote, contact us on 01773 528 101 or email info@excelpress.ltd.uk.